Our team is committed to providing high-performance energy solutions tailored to your needs. To initiate further communication, kindly submit a formal inquiry for the product(s) of your interest.

Our team is committed to providing high-performance energy solutions tailored to your needs. To initiate further communication, kindly submit a formal inquiry for the product(s) of your interest.

As we gaze upon the final lithium battery product—whether a small cylindrical cell or a large pack—the journey from its raw material origins often remains hidden. Creating a high-performance, safe battery is akin to a symphony, composed from the harmony of materials science, precision manufacturing, and intelligent control. Let’s explore and delve into the layers of this process, tracing the entire path from a single cell to a complete pack.

Cell Manufacturing – The Birth of the Battery's "Heart"

This phase transforms raw materials into the core energy-storing components through several precision steps:

Slurry Mixing: Active materials for the cathode and anode are combined with conductive agents and binders, forming a uniform slurry.

Precision Coating: The slurry is evenly coated onto ultrathin metal foils—aluminum for the cathode, copper for the anode—with micron-level accuracy for consistent cell capacity.

Calendering and Slitting: After drying, the coated foils are compressed to precise thickness and density, then sliced into narrow strips with clean, burr-free edges, ready for cell assembly.

Cell Assembly – Housing the Power Core

With the electrodes ready, the next step is to build the battery's functional core and give it a protective home.

The process diverges here based on the final cell shape. For the high-density, space-efficient designs of pouch and prismatic cells, the electrodes are stacked like precise layers of a sandwich, optimizing space and ensuring even internal stress.

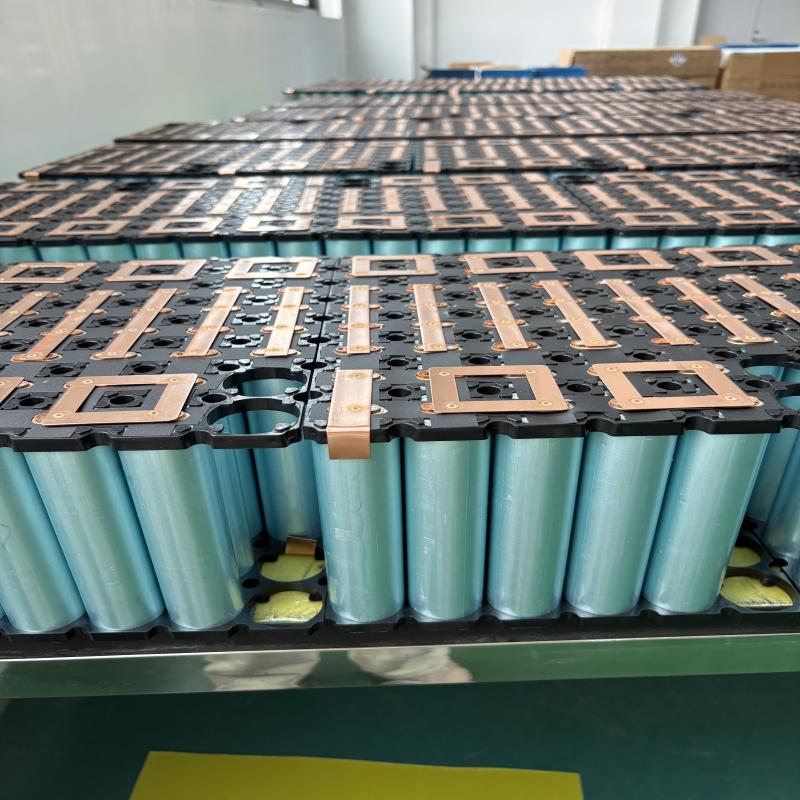

For the classic and robust cylindrical cells (think 18650 or 21700), a high-speed winding process is used. Here, the anode, separator, and cathode are rolled together into a tight “jelly roll,” a mature and highly efficient method.

Next comes sealing the core. Electrode tabs are precision laser-welded to terminals, a critical joint tested for perfection with sensitive helium leak detection. Finally, the core is encapsulated—either inserted into a sturdy steel case (cylindrical/prismatic) or sealed within a flexible, lightweight aluminum-laminated pouch.

Drying and Filling: Cells are baked at 85–105°C under vacuum for 12–24 hours to reduce moisture content to ppm levels. Electrolyte is then precisely metered and injected in a vacuum environment.

Sealing: Immediate hermetic sealing (via laser welding or mechanical crimping) isolates the cell from moisture and oxygen.

Formation and Grading

Formation: The first charging cycle forms a dense SEI (Solid Electrolyte Interphase) film on the anode surface. This "birth certificate" of the cell determines its cycle life, safety, and overall performance.

Grading: Cells undergo full charge-discharge tests to measure actual capacity, internal resistance, and self-discharge. Cells are sorted into matched set less than 2% variance

Battery Pack (PACK) Integration – From "Individual" to "Team"

Cell Screening and Matching: Cells are grouped by nearly identical capacity, voltage, and internal resistance to prevent weakest-link effect.

Assembly and Interconnection: Series/parallel connections use busbars or flexible printed circuits (FPC). Laser welding or bolting achieve ultra-low contact resistance (<0.1 mΩ) and high mechanical strength.

Sensing and Thermal Management: Integrated temperature sensors (typically one per 2–4 cells) along with liquid cooling plates or air channels maintain cell-to-cell temperature differences within 5°C.

Final Pack Assembly

Structural Integration: Modules, BMS, thermal management components (plumbing, pumps, fans), and high-voltage junction boxes (relays, fuses) are mounted within a rugged enclosure that meets stringent mechanical standards for vibration, shock, and crush resistance.

BMS & Harnessing: The Battery Management System—often called the “brain” of the pack—continuously monitors every cell, executes active balancing, manages thermal controls, performs fault diagnosis, and enables multi-layer protection.

Testing & Validation: Completed packs are subjected to IP67/IP68 leak testing and real-world aging cycles to ensure stable, reliable, and durable performance under actual operating conditions.

Our Commitment: Focused on Integration, Committed to Quality

Rigorous Incoming Inspection: Every cell undergoes 100% retesting for capacity, internal resistance, and appearance, with less than 1.5% variance allowed. This ensures weak links are eliminated from the source.

Precision Manufacturing: From cell matching to laser-welded busbar connections, our automated process monitors key parameters in real time, ensuring complete traceability and consistency.

Custom-Tuned BMS: Our BMS platform is tailored with active balancing and intelligent thermal management strategies to maximize cell performance. Every system undergoes comprehensive functional safety testing prior to shipment.

Full-Condition Validation: Every battery pack is subjected to IP68 sealing tests, vibration and shock resistance trials, and high/low-temperature cycling to guarantee reliable operation in real-world environments.

We are your partner who understands cells, excels at integration, and prioritizes quality control—delivering thoroughly validated, reliable energy solutions.

FAQ:

Q: Is a Duracell battery a lithium battery?

A: No. Duracell consumer batteries are alkaline or NiMH. Our rack-mounted lithium battery systems use industrial-grade LiFePO4 cells designed for energy storage applications.

Q: How do I know if I have a lithium battery?

A: Check for "LiFePO4" or "Li-ion" on the label and nominal voltage (3.2V/cell). Our systems clearly display chemistry, capacity, and certification marks for easy identification.

Leave A Message

Scan to Wechat :

Hi! Click one of our members below to chat on